Review Article

Creative Commons, CC-BY

Creative Commons, CC-BY

Quality Assurance of Omega-3 Fatty Acids in Fish Oil Capsules

*Corresponding author: Eva Kuennemann, MVS Pharma GmbH, Leinfelder Str. 62, Leinfelden Echterdingen, Germany.

Received: March 28, 2025; Published: April 03, 2025

DOI: 10.34297/AJBSR.2025.26.003457

Abstract

Omega-3 long-chain Polyunsaturated Fatty Acids (n-3 PUFAs) found in fish oil capsules have a critical role and significance for human health. Particularly EPA and DHA are known for their potential benefits in preventing cardiovascular disease, treating inflammatory conditions, improving early life neurodevelopment, and preventing cognitive decline. n-3 PUFAs are highly prone to oxidation and degradation reactions due to their chemical structure containing several double bonds. Here, we emphasize the importance of quality assurance in the production of omega-3 capsules, from raw material extraction to manufacturing, packaging, and storage. Oxidation protection is identified as a key factor in preserving the freshness and efficacy of omega-3 products. Various factors influencing oxidation are discussed, including exposure to air, temperature, time, light, transition metals, and water. The role of antioxidants in reducing oxidation is highlighted and the importance of monitoring oxidation levels through tests like the TOTOX value. The article emphasizes the need for proper storage, handling and testing of omega-3 capsules to ensure their quality and effectiveness for consumers. The review provides a comprehensive analysis of the literature on omega-3 fatty acids and underscores the significance of quality assurance in delivering high-quality omega-3 products.

Keywords: Fish oil capsule, Omega-3 long-chain polyunsaturated fatty acids, Oxidation, Quality

Abbreviations: ALA: α-linolenic acid; DHA: Docosahexaenoic acid; EE: Ethyl ester; EPA: Eicosapentaenoic acid; GOED: The Global Organization for EPA and DHA Omega-3; IFOS: International Fish Oil Standards; n-3 PUFA: Omega-3 long-chain polyunsaturated fatty acids; TAG: Triacylglycerol

Introduction

Fish oils are among the most popular dietary supplements in the world. They contain significant quantities of omega-3 longchain Polyunsaturated Fatty Acids (n-3 PUFAs) which play a critical role in human health. Almost a century ago, in the year 1929, Burr and Burr discovered that essential fatty acids exist that the human body cannot synthesize itself [1,2]. A lot of the basic research on omega-3 fatty acids was done by Robert George Ackman [3]. He is known as pioneer in the field of lipid analytical chemistry, particularly capillary Gas Liquid Chromatography (GLC) of fatty acids. He developed a number of techniques to study and analyse marine oils that are now used worldwide.

n-3 PUFAs show promise, particularly in the prevention of cardiovascular disease, the treatment of inflammatory disease, improving early life neurodevelopment, preventing cognitive decline, and they have potential benefits to metabolism [4-7].

The characteristic of n-3 PUFAs is a double bond three atoms away from the terminal methyl group in their chemical structure. The three types of omega-3 fatty acids involved in human physiology are α-linolenic acid (ALA), Eicosapentaenoic Acid (EPA), and Docosahexaenoic Acid (DHA). ALA can be found in plants like walnuts, edible seeds, and flaxseeds, while DHA and EPA are found in algae and fish [8]. EPA (20:5, n-3;), has 20 carbon atoms and contains 5 double bonds and from the terminal end the first double bond is three atoms away, therefore it is noted as EPA (20:5, n-3). Similarly, DHA (22:6, n-3) has or 6 double bonds in a carbon chain of 22 carbon atoms, respectively. As with most naturally-produced fatty acids, all double bonds are in the cis-configuration, in other words, the two hydrogen atoms are on the same side of the double bond (Figure 1). Methylene bridges interrupt the double bonds so that two single bonds exist between each pair of adjacent double bonds [9]. At these methylene bridges parts of the carbon chain can be rotated and therefore the fatty acids have no geometrically fixed structure (Figure 1).

Worldwide, there is a rapid increasing demand for n-3 PUFA- rich oils [10]. A lot is provided as omega-3 capsules from many different manufacturers and different qualities are found on the global market. Rainer Proksch, CEO of MVS Pharma wants to provide a premium Omega-3 product to the consumer. For this the necessary quality must be assured in all steps starting from raw material via manufacturing the oil, producing the capsules until packaging, storage and handling at the final consumer. Here, in this review, we collected literature for all these parts and focus on oxidation protection as this is most important to preserve freshness of n-3 PUFAs. This is significant as millions of people consume n-3 PUFAs daily and their effects depend on the quality of the products.

Oxidation of Omega-3 Formulations

n-3 PUFA are extremely prone to oxidation due to the large number of double bonds within the fatty acid chain [11,12]. This leads to fast degradation over time during storage and makes fish oils unstable in the presence of oxygen and to one of the most labile supplements sold to consumers [13]. Oxidation of fish oil supplements will not only result in rancidity but also affect the nutritional value of ingredients. As fish oils oxidize, unoxidized fatty acids reduce and are replaced by a complex ‘soup’ of lipid peroxides and secondary oxidation products like aldehydes and ketones [13]. It has been shown that a large number of saturated and unsaturated aldehydes, ketones, acids, and other products isolated from oxidized oils contribute to undesired flavors and odors.

In Figure 2 the reaction mechanism for fish oil oxidation is shown. The oxidation is a complex reaction consisting of a starting reaction, a chain reaction and a finishing reaction [14,15]. Start is the formation of a radical at one of the double bonds in a n-3 PUFA molecule. This is then the site of reaction with oxygen that leads to the formation of a peroxide radical. Various reactions of these radicals are possible with the long molecules of n-3 PUFAs. Due to the high reactivity of the peroxide radical a chain reaction is the second part of the oxidation where many more radicals develop and many more molecules of n-3 PUFAs degrade. Oxidation of one fatty acid molecule can result in the formation of many different primary and secondary oxidation products, so a very small change in the concentration of a specific fatty acid can result in large amounts of oxidation products. The final third part of the oxidation is the reaction where two radicals get together whereby also a great variety of molecules can be formed [14] (Figure 2).

Factors Determining Oxidation

Oxygen is present in air and therefore it is important to protect fish oil against air exposure at all stages of processing [16]. It is suggested that oils are stored without air and that all residual volumes in a container or in a capsule that is not occupied by the omega-3 oil is filled with nitrogen or with argon. The inert gas argon has a higher density than air and therefore will not evaporate fast.

At higher temperatures oxidation reactions run faster [16-18]. Generally, it is said for chemical reactions that the speed doubles with a 10°C temperature increase. Therefore, it is necessary to control temperature during all stages where fish oil is worked with, stored or transported. Similarly, longer the time, the more reactions can occur and the higher will be the extent of oxidation [19].

Double bonds absorb UV-light and this catalyses the formation of radicals. This is the first step of the oxidation reaction, that is independent of oxygen. With oxygen the peroxide radical is built that leads to very fast chain reactions [15]. However, also without oxygen, UV light accelerates the formation of the radicals of n-3 PUFAs that then degrade to various products, however, much slower than in the presence of oxygen.

All omega-3 products must be protected from sunlight [16]. Glass and plastic containers block UV light and also other materials can be used for protection.

Transition metals like iron and copper catalyse oxidation reactions [20]. Under these conditions chain branching can contribute by the formation of alkoxyl radicals. As these trace metals occur in organism and also fish, it is difficult to completely avoid them [16]. However, one should not add them and limit the contact of n-3 PUFA containing oils with metals like stainless steel. Charged metal ions can be complexed by chelators like citric acid or EDTA to limit their reactivity.

In the presence of water, especially if the H2O content is in excess in liquid or gas form as humidity, the oxidative stability of n-3 PUFAs is affected [16]. The effects of relative humidity on the oxidative stability of spray-dried microencapsulated fish oil during storage was investigated and the longest lag period was observed at 0% relative humidity [21]. It was speculated that anti- or prooxidative roles of water may depend on the structure, composition, and microscopic heterogeneity of the food system.

Oxidation Rate

From the above points it is clear that the rate of oxidation depends on many points. The reaction is faster if oxygen is present, at higher temperatures and under UV-light. Sullivan-Ritter et al., have performed a stability study with liquid omega-3 samples in Triacylglacerol (TAG) and Ethyl Ester (EE) form in open vials at different temperatures [17]. They assumed pseudo-first order rates for the reactions at temperatures between 5°C and 45°C and calculated rate constants. At temperatures above 30°C high oxidation is already seen within the first days with both, hydroperoxide value and anisidine value. In Figure 3 an example calculation shows that depending on quality of the fish oil and the presence of air within 10 days more than 90% of the fish oil easily gets oxidized even when stored at 15°C. The study of Sullivan-Ritter et al., also clearly shows that EE fish oil oxidizes more rapidly than TAG fish oil containing near identical levels of EPA and DHA [17]. It is difficult to compare studies on oxidation rates of omega-3 products as there are not many well-documented studies and the samples and the methods and the conditions like temperature differ a lot [22] (Figure 3).

Antioxidants

The addition of antioxidants to fish oils reduces oxidation [23]. The oxidation reactions cannot be completely prevented. The addition of external antioxidants to fish oils promotes the stability and extends the shelf life of the fish oils [24]. Antioxidants are substances that, when present at low concentrations compared to those of an oxidizable substrate, significantly delays or prevents oxidation. Antioxidants should be added before oxidation starts and peroxide radicals are formed. Many tests have confirmed that adding antioxidants to already oxidized oils does not have significant benefits once the chain reaction of oxidation has already started. Antioxidants are preferably added as early as possible in the process chain of oils [16]. They are necessary to protect from oxidation that might occur already from oxygen that is soluble in the oil. To stabilize bulk and end products containing EPA and DHA antioxidants are used to decrease the rate of oxidation.

The most important antioxidants used are tocopherols [24]. In addition, spice extracts like rosemary, ascorbates, and citric acid are used to inhibit oxidation in omega-3 preparations [12]. Tocopherols prevent the chain reaction during free radical oxidation by reacting themselves with radicals and thereby stopping the formation of additional peroxides and the formation of secondary oxidation products. Citric acid can chelate metal ions that catalyse oxidation reactions and is very effective in postponing oxidative deterioration.

Although radicals develop directly from unsaturated fatty acids, especially those containing multiple double bonds, oxygen is responsible for the chain reaction step [14]. Manufacturers should know the content of antioxidants in the oil components they purchase and handle [24]. During handling and processing like distillation, a small part of antioxidants might be removed or reduced by oxidation. In such cases, it must be essential to reestablish the original levels of added antioxidants. Many tests have confirmed that adding antioxidants to already oxidized oils does not have significant benefits once the chain reaction of oxidation has already started. Antioxidants are preferably added as early as possible in the process chain of oils [16].

Tests for Oxidation

A lot of tests for oxidation products exist [25]. Most common are the following:

The Total Oxidation Index (TOTOX) is a common method used in determining lipid oxidation [25]. It determines both the primary and secondary oxidation products and indicates the overall oxidation states. Therefore, it refers to the final quality of n-3 PUFAs. The TOTOX value is the sum of the p-anisidine value plus two time the peroxide value. The p-anisidine value determines the number of aldehydes, principally 2-alkenals and 2,4-dienals [26]. The peroxide test measures oxidation of iodide by hydroperoxides or by oxidation of Fe2+ to Fe3+ spectrophotometrically [25]. An assay with Thio barbituric acid reactive substances is the spectrophotometrically TBA-test, also called rancidity test [24,25]. It measures malondialdehyde that is created during the oxidation of lipids.

Oxidation in Omega-3 Products

At MVS Pharma research was done on manufacturers of fish oil capsules in different countries like the US and in Europe. Dozens of companies were found. Many available studies show very different quality of available products containing EPA and DHA.

In the Journal of Nutritional Science, 2015 a study by Jackowski et al. evaluated primary and secondary oxidation in all the n-3 PUFA oils available over the counter in retail stores in Canada [27]. A total of 171 supplements from forty-nine brands were assessed, with 50% exceeding voluntary limits for at least one measure of oxidation, and 39% exceeding the international voluntary safety recommendations for Total Oxidation (TOTOX) value. A study from 2024 that analysed 72 omega-3 supplements sold in the USA revealed that 68% of flavoured and 13% unflavoured products exceeded the TOTOX upper limit set by the Global Organization for EPA and DHA [28]. Further studies performed in 2013 and 2015 in South Africa and New Zealand found that more than 80% of supplements tested exceeded recommended levels [29]. Another analysis from New Zealand from 2017 shows that more than 70% of the tested products, 72%, 86% and 77% complied with voluntary industry- set maximum limits on TOTOX value and 91% of the products complied with EPA/DHA content claims [30]. On the other hand, in a study by Jairoun, et al., from the year 2020 and one by Pasini, et al., from 2022 it is stated that most, of the fish oil supplements tested are compliant with the oxidative quality standards [31,32]. So, the awareness of the importance to protect n-3 PUFAs from oxidation might have increased. A quality control of Italian supplements containing fish-oil found substantial agreement with the label [33]. However, the researchers concluded that compliance with the label is not enough to judge a product of good quality. Consequently, it is clear that control and inspection of authenticity, purity, quality, and safety in the whole supply chain of omega-3 supplements is necessary.

A frequent analysis is the measurement of the anisidine and peroxide values and the calculation of the TOTOX value. This states if oxidation is present or absent. The absence of oxidized molecules does not guarantee that EPA and DHA molecules or the TAGs and EEs containing them are present in their form. As radicals form, they can also react to other degradation products. An analysis for the presence of undegraded n-3 PUFAs in the final product would be a proof and could be done with gas chromatography as is performed after purification.

Production Processes and Important Steps to Ensure Quality

The assurance of quality and stability of omega-3 long chain polyunsaturated fatty acid oils has gained importance with millions of people using it [31]. The fact that the major amount of fish oil capsules is sold as supplements gives the responsibility for controlling the product mainly to the manufacturers. Best practice guidelines for oxidation control of marine oils are published by The Global Organization for EPA and DHA Omega-3 (GOED) [16]. GOED has shown many factors that can affect the oxidation of marine oil during and after capsule formation.

Visible Inspection of Omega-3 Capsules

Already per eye strong differences for omega-3 capsules can be seen as presented in Figure 4. In pure form DHA like EPA is a colourless to pale yellow liquid. Both substances do not have a strong colour, as can be seen on the left for a clear hard-gelatine capsule containing a highly purified mixture of EPA and DHA. Due to the presence of other compounds in fish oil, it can appear yellowish or slightly amber. This is shown for a soft gel capsule on the left, where even some aggregates are present. If an air bubble is present in the capsule, it is important to assure that this does not contain oxygen. Responsible manufacturers use the inert gas nitrogen to flush during capsule production, as for example Lonza [34] (Figure 4).

Manufacturing Steps and Protection Measures

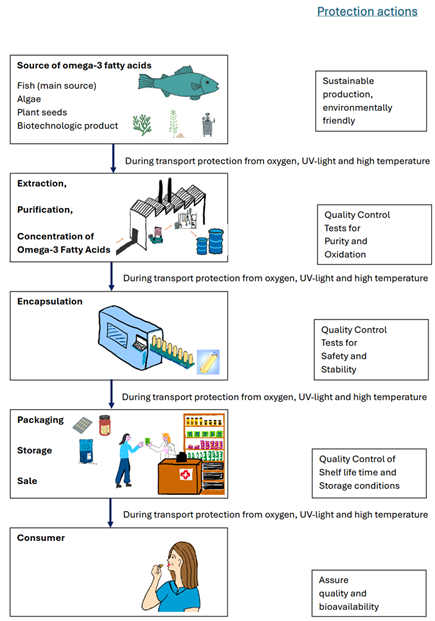

During the production of fish oil, during all processes involved are protections measures necessary to ensure the safety, quality, and efficacy of the final product, compare Figure 5. These protections are designed to minimize contamination, preserve the nutritional integrity of the oil, and ensure that the fish oil meets industry and regulatory standards. Especially, the introduction of accidential oxidation by atmospheric oxygen must be avoided. Figure 5 shows the complete production process from the source where omega-3 fatty acids are biochemically produced to the consumer. Steps are shown where controls to assure quality of omega-3 fatty acids are necessary (Figure 5).

Figure 5: Scheme presenting an overview of the way EPA and DHA take from the source of omega-3 oil to the consumer showing necessary protection measures to assure quality in all processes.

Main Source of Omega-3 Fatty Acids is Fish

Production of capsules containing omega-3 fatty acids starts at the source where omega-3 fatty acids are produced in nature. The raw material typically comes from fish and is extracted from the fish oil e.g., cod liver oil, anchovy, or krill [35]. However, fish does not biosynthesize n-3 PUFAs itself, it acquires them and accumulates them in their tissues as microalgae move up the food chain [36]. Algae produce the n-3 PUFAs DHA and EPA and these can also be extracted from algae oil. Furthermore, plant-based sources like flaxseed or walnut oil contain PUFAs. As more and more omega-3 products are demanded, bacteria are evaluated as host for biosynthesis of omega-3 fatty acids to enable biotechnologal production of DHA and EPA [35].

Extraction and Concentration of the Omega-3 Oil

Fish oil extraction methods were reviewed my Eshari, et al., 2022 [37]. The oil is extracted from the source using methods such as solvent extraction for fish. For plants cold pressing is often used. Using low temperatures during the processing of fish oil can prevent the breakdown of omega-3 fatty acids.

The industrial-scale concentration technologies of n-3 PUFAs have been more and more perfected in the last 20 years. Omega-3 polyunsaturated fatty acids in fish oil are produced and concentrated using adsorption and counter current chromatography. To concentrate the omega-3 content the main step is fractional or molecular distillation or enzymatic processing, typically focusing on EPA and DHA, the key omega-3 fatty acids. Further, low-temperature crystallisation, supercritical fluid extraction, fatty acid solubility differences and urea complexation are used [38]. In 2013, a review stated that there were only a handful of companies worldwide able to produce EPA and/or DHA products with more than 95% purity, but this changed in the last decade because of the growing demand for such products [39]. Gas chromatography with flame ionization detection is a method to identify and quantify omega-3 fatty acids and accurately and precisely and can be used effectively for routine analysis [40]. The omega-3 concentrates may be in the form of free fatty acids, alkyl esters and triacylglycerols, compare chemical structures in (Figure 1).

Purification of Omega-3 Oil

Fish oil can contain different contaminants and impurities like heavy metal contamination. Mercury, lead, and cadmium are toxic when consumed in large amounts. Furthermore, polychlorinated biphenyls that are industrial chemicals can accumulate in fish and pose health risks. Production processes should include refining steps that remove these contaminants. Additionally, environmental pollutants like dioxins may be present in fish and should be minimized or eliminated during oil refinement through distillation or other purification processes [41]. Responsible manufacturers like EPAX analyse all these data and provide certification sheets that the product is free from contaminants and impurities.

For high-percentage omega-3 products further unwanted fats like saturated fatty acids and omega-6 fatty acids are removed. Also, oxidation products can be removed. By these degumming and refining steps, the quality of the fish oil can be improved. Sometimes deodorization is added to eliminate fishy odors or taste [42]. This step can involve steam or vacuum treatment at low temperatures to remove volatile compounds responsible for the smell. For consumers this procedure ensures a more palatable product and the quality is improved [43].

Storage and Transport After Production of the Oil

Immediately after production the oil is stored in a dark barrel, hermetically sealed and filled with argon to provide an inert atmosphere, protected from UV-light and high temperature. Argon is heavier than air and oxygen, therefore it will stay as a protective on top of liquid fish oil. Additionally, dry storage is recommended as humidity can also increase degradation.

In experienced companies, like EPAX, the fish oil is tested for oxygenation by measuring Peroxid- and Anisidine value and the results are marked per each charge [44]. Additionally, the number of added antioxidants is noted. Often transport is involved before the manufacturing of capsules with the omega-3 oil, as frequently the producer of the fish oil is another company than the one making and filling the capsules. Therefore, it is of importance that during this period, proper storage and packaging are guaranteed.

Manufacturing of Capsules

Fish oil containing omega-3 fatty acids is sold as liquid but the administration form as capsules bears several advantages. Capsules can be carried in the bag and stored very easily. As the content has a protection shell by the capsule less special handling and refrigeration is required to maintain freshness. Capsules provide a premeasured dose. Often, they have a longer shelf life when they are wellsealed and less exposed to air, which helps prevent oxidation.

Different capsules have been developed over the years. The main types of capsules are soft and hard capsules [45]. Both can be made of gelatin, bovine gelatin or fish gelatin but also other materials like hydroxypropyl methylcellulose, pullulan and starch that is used for vegetarian capsules.

The shell of the capsule provides a barrier for oxygen. Depending on the material and coating of the capsule oxygen can diffuse well or only in a very limited way [46]. It has been stated that the lower the oxygen permeability of the capsule shells, the safer the fill material is from oxidation and the user is smelling or tasting the fill material. It is known that hard capsules have a much lower oxygen permeability than soft capsules where the ingredients are often prone to oxidation [45]. In a technical reference file for empty hard capsules, it is shown that their hard gelatin capsules have a very low oxygen permeability [47]. In this way, the amount of oxygen that can enter the capsule and react with n-3 PUFAs is extremely restricted. Also, a study in the journal “molecules” shows that encapsulating provided a protective effect to the fish oil and elongated the shelf life of it comparing to the untreated oil sample [48].

Additionally, to choosing the right capsule material during the filling process in capsules oxygen must be excluded. Therefore, closed systems containing the capsule filling machine are flushed with nitrogen [34]. When manufacturing capsules, it is recommended to use whole barrels of omega-3 fish oil entirely. Otherwise, the manufacturer must ensure that the opened barrels are hermetically sealed again and re-filled with argon for protection against oxygenation.

Packaging, Storage and Transport of Capsules

After filling, the capsules must be immediately packaged in an airtight manner to be protected safely. This is done either by immediately filling them into sales packaging such as glass or PE containers, blisters or bags, or by packaging them in bulk for further processing in a way that is airtight and protected from UV-light, high temperature and humidity. When elevated water content is present, the stability of gelatin capsules is affected and subsequently the omega-3 oil that is in the capsule gets more oxidation prone. If the filled capsules are not immediately packaged in the final form, it must be ensured that they are stored only for short time in a cool place. They should be processed as quickly as possible. Fish oil should be stored in dark, opaque bottles to protect it from UV-light exposure. Oxygen scavengers and oxygen absorbers can be used in the form of films, sachets, powders, or as part of the packaging material itself along with other means of preservation such as the use of chemicals, reduced water activity, pH, multilayer composite material, and or vacuum or modified packaging [49].

It has been analysed that the aroma and taste of the omega-3 products generally changes in a negative manner during storage [50]. In a study in Food Science and Nutrition capsulated samples were better protected according to the sensory evaluation scores at the end of the storage period. They analysed fish oil samples belonging to the same company but being provided from different stores. As the storage conditions might have varied the samples showed significant differences in oxidation [50].

Guidance for the Consumer

After the product containing omega-3 fatty acids is sold, the consumer is responsible for proper storage and intake. If the product is purchased in a pharmacy or drug store, the pharmacist and the counter assistant can give recommendations on how to store the article and how and when to take it. After a package with 90 capsules is opened the last capsule is generally only taken after 90 days, but the time of home storage might be even longer. In jars capsules can be protected by inert gas upon packaging, but once the glass is opened air containing oxygen is present. During this time, the capsules that are not additionally packed, might remain only partly protected by the capsule, which can have a massive impact on oxidation. Also, hygiene and microbial contamination must be thought of if capsules are taken out of the jar by hand. It is recommendable that the storage period should not exceed 18 months at ambient temperature [51].

Generally, there are instructions for use and storage conditions of omega-3 capsules written on the package but these are not always complete. In the Journal “Food Science and Nutrition” an interesting study is reported, where they selected omega-3 products that are for sale in the Turkish market with the highest sales figures. For capsules, chewable forms, and syrups it was seen that the storage time and conditions at home are of importance for the quality of the product. Articles were purchased and stored in their own packages at room temperature under dark conditions. For TOTOX values, all samples complied with the limit values at the first opening while 56.3% of the samples out of limits at the end of the storage period [50].

Batch Testing and Quality Control

For a quality product a robust system of traceability should be in place to track the source and handling of the fish oil, from the origin to the consumer, ensuring transparency and accountability. Regular quality control tests should be conducted on the oil during various stages of production. These tests include tests for fatty acid composition. This verifies that the oil contains the correct balance of EPA and DHA and no contaminants or degradation products. Tests for the oxidation levels and rancidity ensure the oil has not oxidized and remains fresh [24]. Testing for microbial and bacterial contamination guarantees the product is free from pathogens.

Regulation and Compliance

The regulations for supplements can be the same as for food. For example, in Germany for the regulation the only need is to notify with few quality documentations the Federal Office of Consumer Protection and Food Safety [52]. Fish oil manufacturers should adhere to GMP standards, which ensure that the product is produced in a clean, controlled environment. This includes monitoring temperature, humidity, and sanitation to prevent contamination. Production should comply with international standards set by organizations such as the International Fish Oil Standards (IFOS), which ensure the oil meets quality and safety criteria [53].

Beneficial Effects of Fish Oil

Results from Clinical Studies

A large amount of literature exists in this field. Here we present only a few examples. Omega-3 fatty acids lower systolic and diastolic blood pressure in people with hypertension and in people with normal blood pressure [54]. Omega-3 fatty acids can reduce heart rate [55]. Scientific study suggests that people with certain circulatory problems, such as varicose veins, may benefit from omega-3. Omega-3 fatty acids stimulate blood circulation and increase fibrin breakdown, a protein involved in blood clotting and scar formation. Omega-3 fatty acids reduce blood triglyceride levels but do not significantly change the LDL or HDL cholesterol level [56]. A meta-analysis done in 2018 found that no effect has been observed after taking a daily one gram of omega-3 fatty acid in individuals with a history of coronary heart disease [57]. However, omega-3 fatty acid supplementation greater than one gram daily for at least a year is effective against cardiac death, sudden death, and myocardial infarction in people who have a history of cardiovascular disease [58]. A 2021 meta-analysis found that supplementation was associated with a reduced risk of myocardial infarction and coronary heart disease [59].

A 2013 systematic review found evidence of benefit for lowering inflammation levels in healthy adults and people with one or more biomarkers of metabolic syndrome [60]. Consumption of omega-3 fatty acids lowers blood markers of inflammation such as C-reactive protein, interleukin 6, and TNF alpha [61]. A 2021 meta- analysis found that supplementation with omega-3 had positive effects on diabetes biomarkers, such as fasting blood glucose and insulin resistance [62]. Meta-analysis has shown that omega-3 fatty acid supplementation demonstrated a modest effect for improving ADHD symptoms [63]. Furthermore, it was concluded that Athletes might have a higher risk insufficiency of n-3 PUFAs and that supplements can provide effective strategies for increasing n-3 PUFA levels [64].

Composition and Dosage

Fish oil supplements typically contain a combination of EPA and DHA. The optimal dosage of omega-3 varies depending on the specific health outcomes being targeted. Clinical studies suggest that a daily intake of 1,000 mg to 3,000 mg of combined EPA and DHA is effective for promoting cardiovascular health, reducing inflammation, and supporting brain function [65].

It was suggested that the right percentage of omega-3 fatty acid in relation to omega-6 fatty acids is important [66]. In Western countries the diet is often very rich in saturated fats what might lead to less flexibility of the cell membranes what can affect the way they work. To promote health and longevity an efficient supplement with good quality can enhance the appropriate functions of the body [2].

Safety and Side Effects

Fish oil is generally considered safe when taken at appropriate doses. The most common side effects include gastrointestinal discomfort, such as burping or indigestion, especially when taken in high doses. In a systematic meta-analysis of clinical trials, it was found that patients receiving high‐dose purified EPA may incur additional bleeding risk, although its clinical significance is very modest [67].

As described before, it is important to choose a high-quality supplement that is free of contaminants, such as heavy metals or PCBs, which can be present in poorly sourced fish oils. Also, it is essential to guarantee that the fatty acids are not oxidized to ensure safety.

Harmful Effects of Oxidized Lipids

Lipid peroxides formed through the oxidation of n-3 PUFAs are absorbed in the gut [68]. Their active transport and subsequent oxidation may be important in atherogenesis [69]. Lipid peroxides also partially decompose to secondary oxidation products in the gut which are absorbed. Then the omega-3 peroxides may lead to lipid membrane peroxidation, cell damage, and oxidative stress. Membrane lipid peroxidation results in altered membrane fluidity, transport, and cell signalling which may be an important disease mechanism.

Feeding of oxidized PUFAs to rats led to growth retardation, intestinal irritation, liver and kidney enlargement, hemolytic anemia, decreased vitamin E, increased lipid peroxides and inflammatory changes in the liver, cardiomyopathy, and potentially malignant colon cell proliferation [70]. Major secondary oxidation products of omega-3 oils have been shown to cause liver damage and toxicity in DNA [71,72].

For clinical trials it would be good to assess the quality, especially the presence of oxidation products of the omega-3 supplements.

Bioavailability and Absorption

Bioavailability refers to the speed of absorption and the quantity of the substance absorbed. The speed can be understood as the rate at which the substance is absorbed in the gastrointestinal tract and reaches the portal system. Absorption of the substance occurs in the gastrointestinal tract depending on many factors. The extent of absorption and the speed of substance transport to the portal circulation describe the bioavailability. On the other hand, bioavailability can also be considered as the amount of substance that reaches the systemic circulation or the place of physiological activity [73]. Only part of the absorbed n-3 PUFAs reached the systemic circulation. Therefore, there is difference in amount on how the bioavailability is determined and this is important for pharmacokinetics and dietary planning.

The bioavailability of omega-3 fatty acids is influenced by factors such as the form in which the fish oil is consumed, triglyceride compared to ethyl ester, the presence of food, and individual metabolic factors. Studies indicate that 3-n PUFAs in triglyceride form are more bioavailable than those in ethyl ester form [74]. The efficiency of absorption for free fatty acids lies between these. For this reason, many high-quality omega-3 supplements are designed with a phospholipid or triglyceride-based formulation to enhance absorption. However, a study by Nordoy et al.,1991, showed that n-3 fatty acids in fish oil given as ethyl esters or triglycerides were equally well absorbed [75]. Eicosapentaenoic and docosahexaenoic acids were also equally absorbed. Another study by Dyerberg et al. concluded that the bioavailability of EPA and DHA from resterilised TAG was superior compared with natural fish oil, whereas the bioavailability from ethyl esters was inferior [74]. Free fatty acid bioavailability did not differ significantly from natural triglycerides. It is also important to consider the influence of the capsule on release of omega-3 oil in the stomach to assess bioavailability [76].

Conclusion

Omega-3 fish oil capsules, particularly those rich in EPA and DHA, offer significant health benefits supported by a robust body of scientific evidence. These benefits are most pronounced in cardiovascular health, cognitive function, and inflammation management. When selecting a supplement, the form of omega-3s (triglyceride vs. ethyl ester), dosage, and product quality are key factors to consider. During fish oil production protection measurements are essential for ensuring a high-quality, safe, and effective product, especially as n-3 PUFAs are extremely prone to oxidation. By following strict guidelines for sourcing, refining, and testing, fish oil producers can deliver a product that supports consumer health while minimizing environmental and health risks [77]. Additional to manufacturing conditions, packaging and storage situations that provide an inert atmosphere, low temperature and avoid light are important at stores. Also, the consumer must be aware of this and care not to excess the shelf-life period. Overall, omega-3 supplementation remains a valuable tool for supporting long-term health, though users should adhere to recommended dosages and consult with a healthcare professional, especially if taking medications or managing chronic health conditions.

Acknowledgements

This work was initiated and financed by Rainer Proksch, the CEO of MVS Pharma GmbH, Germany. We are very thankful for his efforts to find clear scientific solutions to provide high quality products. No financial interest or any conflict of interest exists, as the purpose of this review clearly is to analyse existing literature showing where protection measures and tests are necessary to assure quality in omega-3 products. Special thanks to Mihaela Achieve and Donka Staykova for the research of companies providing omega- 3 capsules. Thank you also to Adham Mohamed for checking the guidelines and figures. We are very grateful to the whole team of MVS Pharma for support of this project.

Conflicts of Interest

None.

References

- Burr GO, Burr MM (1929) A new deficiency disease produced by the rigid exclusion of fat from the diet. J Biol Chem 82(2): 345-367.

- Caramia G (2008) [The essential fatty acids omega-6 and omega-3: from their discovery to their use in therapy]. Minerva Pediatr 60(2): 219-233.

- (2024) Wikipedia. Robert Ackman https://en.wikipedia.org/wiki/Robert_Ackman.

- Calder PC (2004) n-3 Fatty acids and cardiovascular disease: evidence explained and mechanisms explored. Clin Sci (Lond) 107(1): 1-11.

- Calder PC (2013) Omega‐3 polyunsaturated fatty acids and inflammatory processes: nutrition or pharmacology? Br J Clin Pharmacol 75(3): 645-662.

- Karr JE, Alexander JE, Winningham RG (2011) Omega-3 polyunsaturated fatty acids and cognition throughout the lifespan: a review. Nutr Neurosci 14(5): 216-225.

- Kalupahana NS, Claycombe KJ, Moustaid Moussa N (2011) (n-3) Fatty Acids Alleviate Adipose Tissue Inflammation and Insulin Resistance: Mechanistic Insights. Adv Nutr 2(4): 304-316.

- Miller MR, Nichols PD, Carter CG (2008) n -3 Oil sources for use in aquaculture – alternatives to the unsustainable harvest of wild fish. Nutr Res Rev 21(2): 85-96.

- Patted PG, Masareddy RS, Patil AS, Kanabargi RR, Bhat CT (2024) Omega-3 fatty acids: a comprehensive scientific review of their sources, functions and health benefits. Future J Pharm Sci 10(1): 94.

- Marsol Vall A, Aitta E, Guo Z, Yang B (2022) Green technologies for production of oils rich in n-3 polyunsaturated fatty acids from aquatic sources. Crit Rev Food Sci Nutr 62(11): 2942-2962.

- Benzie IF (1996) Lipid peroxidation: a review of causes, consequences, measurement and dietary influences. Int J Food Sci Nutr 47(3): 233-261.

- Pak CS (2005) Stability and quality of fish oil during typical domestic application. Published online. https://www.researchgate.net/publication/255646990_STABILITY_AND_QUALITY_OF_FISH_OIL_DURING_TYPICAL_DOMESTIC_APPLICATION.

- Shahidi F, Zhong Y (2010) Lipid oxidation and improving the oxidative stability. Chem Soc Rev 39(11): 4067-4079.

- Valgimigli L (2023) Lipid Peroxidation and Antioxidant Protection. Biomolecules 13(9): 1291.

- Xu L, Davis TA, Porter NA (2009) Rate Constants for Peroxidation of Polyunsaturated Fatty Acids and Sterols in Solution and in Liposomes. J Am Chem Soc 131(36): 13037-13044.

- (2017) Global Organization for EPA and DHA Omega-3s (GOED). Best Practice Guidelines: Oxidation Control. https://goedomega3.com/storage/app/media/pdf/GOED%20Best Practice%20Guidelines%20on%20Oxidation%20Control.pdf.

- Sullivan Ritter JC, Budge SM, Jovica F, Reid AM (2015) Oxidation Rates of Triacylglycerol and Ethyl Ester Fish Oils. J Am Oil Chem Soc 92(4): 561-569.

- Sullivan JC, Budge SM, St Onge M (2011) Modeling the primary oxidation in commercial fish oil preparations. Lipids 46(1): 87-93.

- Yan Wang, Qianwen Fu, Yu Hu, Lei Hua, Haiyang Li, et al. (2023) Determination of oxidative deterioration in edible oils by high-pressure photoionization time-of-flight mass spectrometry. Food Chem 424: 136260.

- Gardner HW (1989) Oxygen radical chemistry of polyunsaturated fatty acids. Free Radic Biol Med 7(1): 65-86.

- Baik MY, Suhendro EL, Nawar WW, McClements DJ, Decker EA, et al. (2004) Effects of antioxidants and humidity on the oxidative stability of microencapsulated fish oil. J Am Oil Chem Soc 81(4): 355-360.

- Hidefumi Yoshii, Takeshi Furuta, Hirokazu Siga, Shigeru Moriyama, Takashi Baba, et al. (2002) Autoxidation Kinetic Analysis of Docosahexaenoic Acid Ethyl Ester and Docosahexaenoic Triglyceride with Oxygen Sensor. Biosci Biotechnol Biochem 66(4): 749-753.

- Zuta PC, Simpson BK, Zhao X, Leclerc L (2007) The effect of α-tocopherol on the oxidation of mackerel oil. Food Chem. 100(2): 800-807.

- (2020) The Stabilizing Effect of Antioxidants in Fish Oils. Mina Oline Odden. Norwegian University of Science and Technology Faculty of Natural Sciences Department of Biotechnology and Food Science https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/2782582.

- Abeyrathne EDNS, Nam K, Ahn DU (2021) Analytical Methods for Lipid Oxidation and Antioxidant Capacity in Food Systems. Antioxidants 10(10): 1587.

- (2024) American Oil Chemists’ Society (AOCS). Official Methods and Recommended Practices of the AOCS, p-Anisidine Value. https://library.aocs.org/Cd-18-90/

- Jackowski SA, Alvi AZ, Mirajkar A, et al. (2015) Oxidation levels of North American over-the-counter n -3 (omega-3) supplements and the influence of supplement formulation and delivery form on evaluating oxidative safety. J Nutr Sci 4: 30.

- Hands JM, Anderson ML, Cooperman T, Frame LA (2024) A Multi-Year Rancidity Analysis of 72 Marine and Microalgal Oil Omega-3 Supplements. J Diet Suppl 21(2): 195-206.

- Opperman M, Benade S (2013) Analysis of the omega-3 fatty acid content of South African fish oil supplements: a follow-up study: Cardiovasc J Afr 24(8): 297-302.

- Gerard Bannenberg, Craig Mallon, Holly Edwards, Derek Yeadon, Kevin Yan, et al. (2017) Omega-3 Long-Chain Polyunsaturated Fatty Acid Content and Oxidation State of Fish Oil Supplements in New Zealand. Sci Rep 7(1): 1488.

- Jairoun AA, Shahwan M, Zyoud SH (2020) Fish oil supplements, oxidative status, and compliance behaviour: Regulatory challenges and opportunities. PLoS One 15(12): 0244688.

- Pasini F, Gómez Caravaca AM, Blasco T, Cvejić J, Caboni MF, Verardo V (2022) Assessment of Lipid Quality in Commercial Omega-3 Supplements Sold in the French Market. Biomolecules 12(10): 1361.

- Nevigato T, Masci M, Caproni R (2021) Quality of Fish-Oil-Based Dietary Supplements Available on the Italian Market: A Preliminary Study. Molecules 26(16): 5015.

- (2025) Lonza. Capsugel® Liquid-Filled Capsule Portfolio. Published online. https://www.lonza.com/capsules-health-ingredients/nutraceutical-solutions/dosage-form-solutions/licaps-liquid-filled-capsules.

- Qin J, Kurt E, LBassi T, Sa L, Xie D (2023) Biotechnological production of omega-3 fatty acids: current status and future perspectives. Front Microbiol 14: 1280296.

- (2024) NIH, National Institute of Health. Omega-3 Fatty Acids Fact Sheet for Health Professionals. omega-3 long-chain polyunsaturated fatty acids.

- Fatemeh Eshari, Mehdi Taati Keley, Sajjad Tajeddini (2022) A Review of the fish oil extraction methods and omega 3 concentration technologies. The United Nations University, Fisheries Training program, Iceland 14(3).

- Wanasundara UN, Wanasundara J, Shahidi F (2002) Omega-3 Fatty Acid Concentrates: a Review of Production Technologies. In: Alasalvar C, Taylor T, eds. Seafoods - Quality, Technology and Nutraceutical Applications. Springer Berlin Heidelberg 157-174.

- Lembke P (2013) Production Techniques for Omega-3 Concentrates. In: Omega-6/3 Fatty Acids. Nutrition and Health. Humana Press, Totowa, NJ.

- Muhammad Alinafiah S, Azlan A, Ismail A, Mahmud Ab Rashid NK (2021) Method Development and Validation for Omega-3 Fatty Acids (DHA and EPA) in Fish Using Gas Chromatography with Flame Ionization Detection (GC-FID). Molecules 26(21): 6592.

- Burca N, Watson RR (2014) Chapter 36 - Fish Oil Supplements, Contaminants, and Excessive Doses. In: Watson RR, De Meester F, eds. Omega-3 Fatty Acids in Brain and Neurological Health. Academic Press 447-454.

- Song G, Zhang M, Peng X, Yu X, Dai Z, Shen Q (2018) Effect of deodorization method on the chemical and nutritional properties of fish oil during refining. LWT 96: 560-567.

- Motalebi Moghanjoghi AA, Hashemi G, Mizani M, Gharachorloo M, Tavakoli HR (2015) The effects of refining steps on Kilka (Clupeonella delicatula) fish oil quality. Iran J Fish Sci 14(2): 382-392.

- (2025) Epax. Oceans of Possibilities. https://www.epax.com/.

- Kathpalia H, Doshi G (2014) Recent trends in Hard Gelatin capsule delivery System 4(2).

- Rahmani Manglano NE, Guadix EM, Jacobsen C, García Moreno PJ (2023) Comparative Study on the Oxidative Stability of Encapsulated Fish Oil by Monoaxial or Coaxial Electrosprayingand Spray-Drying. Antioxidants 12(2): 266.

- (2023) Lonza Capsules & Health Ingredients. Technical Reference File Empty Hard Capsules. https://www.lonza.com/knowledge-center/chi/capsules/2023-technical-reference-file.

- Selim KA, Alharthi SS, Abu El Hassan AM, Elneairy NA, Rabee LA, et al. (2021) The Effect of Wall Material Type on the Encapsulation Efficiency and Oxidative Stability of Fish Oils. Molecules 26(20): 6109.

- Gupta P (2023) Role of oxygen absorbers in food as packaging material, their characterization and applications. J Food Sci Technol 61(2): 1-11.

- Yenipazar H, Şahin Yeşilçubuk N (2022) Effect of packaging and encapsulation on the oxidative and sensory stability of omega‐3 supplements. Food Sci Nutr 11(3): 1426-1440.

- Suzan AJ, Garcia PHD, Furlan CPB, et al. (2022) Oxidative stability of fish oil dietary supplements and their cytotoxic effect on cultured human keratinocytes. NFS J 29: 1-7.

- (2025) Bundesamt für Verbraucherschutz und Lebensmittelsicherheit,BVL (Federal Office of Consumer Protection and Food Safety. Nahrungsergänzungsmittel. https://bvl.bund.de/DE/Arbeitsbereiche/01_Lebensmittel/ 04_AntragstellerUnternehmen /03_NEM /lm_nahrungsErgMittel_node.html.

- (2025) International Fish Oil Standards (IFOSTM). https://www.nutrasource.ca/certifications-by-nutrasource/international-fish-oil-standards-ifos/.

- Miller PE, Van Elswyk M, Alexander DD (2014) Long-Chain Omega-3 Fatty Acids Eicosapentaenoic Acid and Docosahexaenoic Acid and Blood Pressure: A Meta-Analysis of Randomized Controlled Trials. Am J Hypertens 27(7): 885-896.

- Mori TA, Beilin LJ (2004) Omega-3 fatty acids and inflammation. Curr Atheroscler Rep 6(6): 461-467.

- Weintraub HS (2014) Overview of prescription omega-3 fatty acid products for hypertriglyceridemia. Postgrad Med 126(7): 7-18.

- Theingi Aung, Jim Halsey, Daan Kromhout, Hertzel C Gerstein, Roberto Marchioli, et al. (2018) Associations of Omega-3 Fatty Acid Supplement Use with Cardiovascular Disease Risks: Meta-analysis of 10 Trials Involving 77 917 Individuals. JAMA Cardiol 3(3): 225-234.

- Casula M, Soranna D, Catapano AL, Corrao G (2013) Long-term effect of high dose omega-3 fatty acid supplementation for secondary prevention of cardiovascular outcomes: A meta-analysis of randomized, placebo-controlled trials [corrected]. Atheroscler Suppl 14(2): 243-251.

- Bernasconi AA, Wiest MM, Lavie CJ, Milani RV, Laukkanen JA (2021) Effect of Omega-3 Dosage on Cardiovascular Outcomes. Mayo Clin Proc 96(2): 304-313.

- Robinson LE, Mazurak VC (2013) N-3 Polyunsaturated Fatty Acids: Relationship to Inflammation in Healthy Adults and Adults Exhibiting Features of Metabolic Syndrome. Lipids 48(4): 319-332.

- Li K, Huang T, Zheng J, Wu K, Li D (2014) Effect of Marine-Derived n-3 Polyunsaturated Fatty Acids on C-Reactive Protein, Interleukin 6 and Tumor Necrosis Factor α: A Meta-Analysis. PLoS One 9(2): 88103.

- Felipe Mendes Delpino, Lílian Munhoz Figueiredo, Bruna Gonçalves Cordeiro da Silva, Taiciane Gonçalves da Silva, Gicele Costa Mintem, et al. (2022) Omega-3 supplementation and diabetes: A systematic review and meta-analysis. Crit Rev Food Sci Nutr 62(16): 4435-4448.

- Bloch MH, Qawasmi A (2011) Omega-3 Fatty Acid Supplementation for the Treatment of Children With Attention-Deficit/Hyperactivity Disorder Symptomatology: Systematic Review and Meta-Analysis. J Am Acad Child Adolesc Psychiatry. 50(10): 991-1000.

- Ralf Jäger, Jeffery L Heileson, Sidney Abou Sawan, Broderick L Dickerson, Megan Leonard, et al. (2025) International Society of Sports Nutrition Position Stand: Long-Chain Omega-3 Polyunsaturated Fatty Acids. J Int Soc Sports Nutr 22(1): 2441775.

- Johanna T Dwyer, Richard A Bailen, Leila G Saldanha, Jaime J Gahche, Rebecca B Costello, et al. (2018) The Dietary Supplement Label Database: Recent Developments and Applications. J Nutr 148: 1428S-1435S.

- Simopoulos AP (2002) The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomed Pharmacother 56(8): 365-379.

- Javaid M, Kadhim K, Bawamia B, Cartlidge T, Farag M, et al. (2024) Bleeding Risk in Patients Receiving Omega‐3 Polyunsaturated Fatty Acids: A Systematic Review and Meta‐Analysis of Randomized Clinical Trials. J Am Heart Assoc 13(10): 032390.

- Staprãns I, Rapp JH, Pan XM, Kim KY, Feingold KR (1994) Oxidized lipids in the diet are a source of oxidized lipid in chylomicrons of human serum. Arterioscler Thromb 14(12): 1900-1905.

- J T Salonen, K Nyyssönen, R Salonen, E Porkkala Sarataho, T P Tuomainen, et al. (1997) Lipoprotein Oxidation and Progression of Carotid Atherosclerosis. Circulation 95(4): 840-845.

- Esterbauer H (1993) Cytotoxicity and genotoxicity of lipid-oxidation products. Am J Clin Nutr 57(5 Suppl):779S-785S; discussion 785S-786S.

- Bartsch H, Nair J (2006) Chronic inflammation and oxidative stress in the genesis and perpetuation of cancer: role of lipid peroxidation, DNA damage, and repair. Langenbecks Arch Surg 391(5): 499-510.

- Marnett LJ (1999) Lipid peroxidation-DNA damage by malondialdehyde. Mutat Res 424(1-2): 83-95.

- Schuchardt JP, Hahn A (2013) Bioavailability of long-chain omega-3 fatty acids. Prostaglandins Leukot Essent Fatty Acids 89(1): 1-8.

- Dyerberg J, Madsen P, Møller JM, Aardestrup I, Schmidt EB (2010) Bioavailability of marine n-3 fatty acid formulations. Prostaglandins Leukot Essent Fatty Acids 83(3): 137-141.

- Nordøy A, Barstad L, Connor WE, Hatcher L (1991) Absorption of the n-3 eicosapentaenoic and docosahexaenoic acids as ethyl esters and triglycerides by humans. Am J Clin Nutr 53(5): 1185-1190.

- Kotsoni E, Daukšas E, Aas GH, Rustad T, Tiwari BK, Cropotova J (2024) Quality Assessment of Fish Oil Obtained after Enzymatic Hydrolysis of a Mixture of Rainbow Trout (Oncorhynchus mykiss) and Atlantic Salmon (Salmo salar) Rest Raw Material Pretreated by High Pressure. Mar Drugs 22(6): 261.

- Boyd LC, King MF, Sheldon B (1992) A rapid method for determining the oxidation of n‐3 fatty acids. J Am Oil Chem Soc 69(4): 325-330.

We use cookies to ensure you get the best experience on our website.

We use cookies to ensure you get the best experience on our website.